- Hoses

- Hose for Automatic Applications

- In-Line Hose

- Hose Hanger

Hoses

Precision wound and calibrated for uniform temperature control

- Durable nine layer construction for superior dielectric and thermal insulation

- Bend radius as small as 8”

- Several temperature control options

- Quick-disconnect electrical plugs with stainless steel conduit

- Hose hanger assembly offer support for both manual and automatic applications

- Available in lengths of 3, 5, 8, 12, 16 and 20 feet

Supply Unit Options

- Supply unit options allows for maintenance supervision/control of the supply units

- Diagnostic tools for regular maintenance up keep

- Available on 2300 and 2400 series systems

Operator Panel Lockout

Operator Panel Lockout

Operator Panel Lockout Open

- Operator Panel Lockout allows maintenance supervisors to set desired temperatures for application

- Locks out operators from adjusting temperatures without supervision

- Access holes are provided so operators can turn the power and pump on/off, put the unit in standby mode, and utilize the self-diagnostic digital temperature readout

- Easy to use key access for adjustment

Flow Valve Adjustment Lockout

Flow Adjustment Lockout

- Flow valve adjustment lockout allows maintenance supervisors to set desired adhesive flow and locks out operators from adjusting without supervision

- Regulation and control of adhesive flow increases cost savings and profitability

- Easy to use key access for adjustment

Glue Pressure Gauge Assembly

Glue Pressure Gauge Assembly

- Glue manifold pressure gauge assembly allows for fine tuning of adhesive pressure/flow

- Quick view access to monitor current pressure rate

- Accurate control of adhesive output yields high standards for product quality assurance

- Helps to diagnose wear and tear on flow valve, pump or motor for easy maintenance up keep

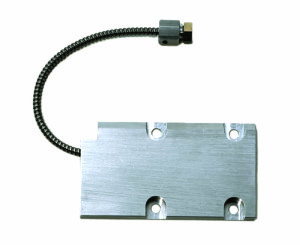

Flow Valve Heater

Flow Valve Heater

- Flow valve heater option allows for higher melt rates or increased temperature for high melt point adhesives

- Enhances flow for thicker high temperature adhesives

- High Melt Rate packages can be added to the system as well to provide additional increased temperatures

Motors

Motors

- Various AC and DC motor options can be added to the system to fine tune adhesive output and match differing adhesive formulas.

- Fixed speed AC motors offered in different rpm and horsepower configurations

- Variable speed DC drives available for line following systems

Foot Pedal Control Package

Foot Pedal

- Foot pedal control can be added as on option for manual control of automatic applicators

- Allows for precision control in manual applications

- Cost savings option for phase 1 to phase 2 operations, where manual operations are currently used, but automation is in the near future

Timer and Custom Control Box Systems

- Custom Control Box

- Timed Based Control

- Automated timing systems and sensing systems available for pattern control for simple to complex automated applications

- Custom control boxes have been engineered for 18” to 165” bridge systems

- Combined photo and relay logic

- Independent on/off control of each module allows for custom length and width detection

- Safety protection prevents glue flow unless product is sensed

- Quick release electrical connections

Bracketry Options

Vertical Feed Bracket

Bracketry

- In stock standard and custom extruded aluminum bracketry options for easy mounting of automatic applicators

Pneumatics

Pneumatics

- In stock pneumatic supplies for fully engineered turn-key automatic applications and spare parts orders