New garage doors are significantly different then the garage doors of just a couple decades ago that many of us grew up with. According to a recent article in “This Old House”, today’s garage doors are thicker, stronger and better insulated then the garage doors of yore. Much of this change is due to the fact that they are insulated when manufactured, a process made possible by new spray adhesive equipment that allows for fast and easy application of adhesive materials in garage door construction and assembly. Here at Sure Tack Systems, we offer a variety of hot melt spray adhesive systems that are ideal for the manufacturing of modern garage doors.

Why Insulated Garage Doors?

Once made primarily of wood, most new garage doors are constructed from metals, like steel and aluminum, or plastic. While this has made doors lighter, cheaper and in many ways easier to maintain, it has cut out the natural insulation effect that wood once provided. Most garage door manufacturers now install some sort of fiberglass radiant insulation to the back of the doors during the assembly process.

The application of adhesives to secure the insulation on the garage door has often presented a problem as the application process can be time consuming and traditional adhesives often have extended drying times that hold up the assembly process. But with the development of the kind of faster drying hot melt adhesives and both automatic and manual adhesive spray systems that Sure Track Systems offers, the entire process has become streamlined, simplified and economically more feasible.

Garage Door Application

About Our Application Systems for Garage Doors

Sure Track Systems has been offering innovative solutions to companies in diverse industries that increase their production output, lower their costs and make the entire assembly process more environmentally friendly for more than 30 years. In fact, according to a report by Adhesives.org, the major benefits of hot melt spray adhesives are that they are fast processing, safe, gap filling, environmentally friendly and shipment and storage efficient. Not only that, but the use of them is growing year after year, meaning those that want to stay competitive need to at least explore the possibilities they offer.

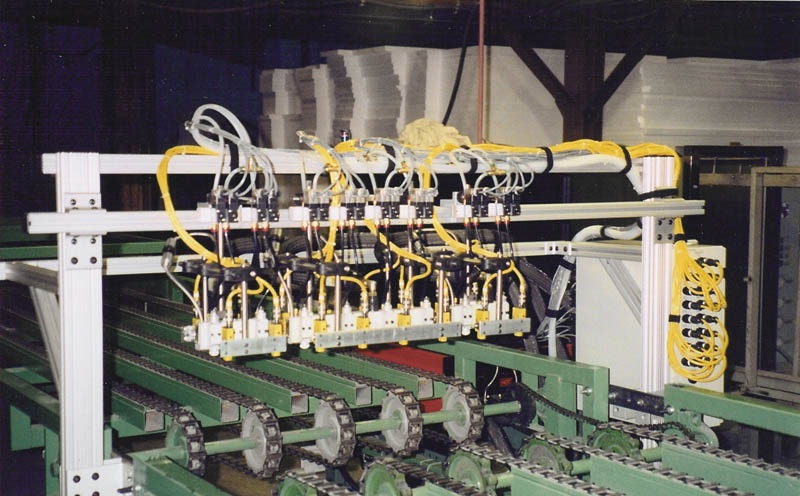

Our hot melt application systems are designed for both large-scale automated assembly lines and smaller facilities that require manual precision. Whether you’re securing insulation with automated spray heads or using extrusion applicators combined with supply units, our solutions improve output, reduce costs, and ensure lasting quality.

Call us at (800) 580-2803 to learn how Sure Tack Systems can help revolutionize your garage door manufacturing process.